Cold Storage Doors

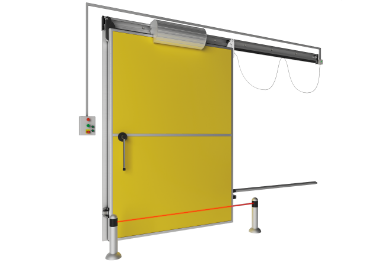

PFI lateral sliding doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Lateral sliding doors work with the principle of sliding to the right or left. Single or double blade options are available. All PFI lateral sliding doors can be equipped with an automation system, a lock, a viewing window, a kick plate, etc.

PFI vertical sliding doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Vertical sliding doors work with the principle of sliding to up and down. All PFI vertical sliding doors can be equipped with an automation system, a lock, a viewing window, a kick plate, etc. Moreover it is provided with a “parachute break” safety device against steel cable break system or malfunction.

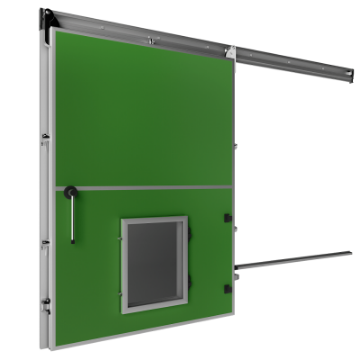

The STN 9 and STN 12 sliding doors can be equipped in order to be used for controlled atmosphere applications. The special closed cells air foam gaskets, together with the exclusive stainless steel eccentric clenching system, guarantee a perfect gas tightness, and a thermal seal too. These doors are provided with a glazed inspection hatch, that can even be supplied to be fixed directly on the cold room wall.

PFI manufactures sliding doors provided with meat rail slide-way (SPG) in two versions. The first one is called “swan neck” due to the cantilever stainless steel structure that keeps the slide way passage free. The second one is called “interrupted rail” and presents the sliding door track positioning just below the slide way passage. Therefore the sliding track presents an interruption to allow the meat rail to pass through.

PFI hinged doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Single or double blade options are available. All PFI hinged doors can be equipped with an automatic door closer, a viewing window, a kick plate, etc.

It works as double-bladed by opening rightward and leftward. It is available both for positive temperature with a 9 cm blade thickness (CTN9), and negative temperature application with a 12 cm blade thickness provided with heaters (CBT12). It is used in cases that require passage area that a single blade cannot cover (proposed above 130 cm). The preferred side is designed as blind frame by adding special anodized aluminium and strike plate. They are equiped with an external locking system and internal panic-button.

PFI monorail hinged doors (CPG) are specially produced according to the monorail dimensions. By using a special hygienic brush and panels of the same color as the door installed inside the frame, we are minimizing air passage. They are manufactured as single or double blade. All PFI hinged doors can be equipped with an automatic door closer, a viewing window, a kick plate, etc.

PFI TAF doors are used as passage doors between production, processing, and corridors where thermal insulation doesn't exist. TAF doors are produced as single or double blade alternatives. These doors blades are equipped with a viewing window and can be fixed at 90 degrees. They belong to semi-insulated door class which have a 40 mm thickness of monolithic blade insulated with high density PU foam injection. PFI TAF doors are used to allow people or wheelbarrows to move quickly and easily to processing rooms in industrial kitchens, food, medicine and industrial facilities. These doors open 90 degrees in both direction. Plexiglass windows are used as standard on all door blades to avoid any accident.

Thanks to their durability and washable surfaces, PFI service doors are suitable for production offices, processing rooms, locker rooms and ablution areas in the food and pharmaceutical industry. These doors can be produced as single or double blades. They belong to semi-insulated door class which have 40 mm thickness of monolithic blade insulated with high density PU foam injection. PFI service doors are equipped with hinges made of composite material, cylinder lock of European origin and plastic ergonomic handles.

Maximizing Efficiency and Sustainability with PFI Cold Storage Doors

In the realm of temperature-sensitive goods storage, cold storage solutions are essential for maintaining product integrity, safety, and longevity. These systems are engineered to provide a consistently chilled environment tailored to the specific requirements of perishable items such as food, pharmaceuticals, and chemicals. The core purpose of cold storage units is to inhibit the growth of microorganisms, ensure regulatory compliance, and ultimately, preserve the quality and shelf-life of the inventory contained within.

A critical component of these sophisticated refrigeration systems is the cold storage door. A door's foundational role includes:

- Creating an Optimal Seal: To prevent the loss of cold air and block the ingress of warm air, which can result in energy wastage and potential spoilage of stored goods.

- Regulating Traffic Flow: An efficient doorway enables quick and secure access for personnel and goods, minimizing door open times, and maintaining the internal temperature.

- Ensuring Durability and Safety: Doors must withstand frequent usage, resist wear from machinery and human interaction, and enhance operational safety protocols.

The effectiveness of PFI (Protected Farms Inc.) cold storage doors is measured by their ability to contribute to the overall efficiency and sustainability of the cold storage system. These specialized doors are designed to accommodate rapid movement, withstand harsh conditions, provide superior insulation, and minimize energy consumption. By focusing on innovative technology and quality materials, PFI cold storage doors seek to deliver performance that aligns with the evolving demands of energy conservation and operational proficiency in the cold storage industry.

The Role of Insulation in PFI's Cold Storage Doors

Insulation is a pivotal component in the design and function of PFI's cold storage doors, providing a barrier to the transfer of heat and ensuring that temperature-controlled environments maintain their integrity. The efficiency of a cold storage facility hinges largely on the ability of its doors to insulate properly.

Thermal Performance: PFI utilizes state-of-the-art insulating materials that minimize thermal bridging and maximize R-values – a measure of thermal resistance. Higher R-values equate to better insulation, meaning less energy is required to maintain desired temperatures inside the cold storage unit.

Energy Conservation: With robust insulation, PFI's doors assist in reducing the overall energy consumption of the facility. They help in maintaining consistent temperatures, which reduces the workload on cooling systems. This is not only cost-effective for operators but also aligns with sustainability goals by lowering the facility's carbon footprint.

Product Integrity: The cold chain's integrity is paramount. Fluctuating temperatures can compromise the quality and safety of perishable goods. PFI’s insulated doors provide an essential defense against such fluctuations, securing product quality from farm to table.

Environmental Control: Insulation plays a vital role in controlling humidity and preventing condensation – factors that can affect not only the products but also the door mechanisms themselves. By managing these environmental parameters, PFI's doors remain reliable and durable over time.

Cost-Effectiveness: While high-quality insulation may represent an initial investment, the cost savings over time through reduced energy bills make PFI's insulated cold storage doors a financially sound choice for businesses that prioritize efficiency.

The profound impact of insulation in cold storage doors is clear. By integrating superior insulating materials and technology, PFI ensures that its cold storage doors provide maximum efficiency and sustainability, propelling businesses forward in their pursuit of operational excellence.

CONTACT US

Understanding the Technology Behind PFI's Cold Storage Doors

PFI's cold storage doors are at the forefront of innovation, designed to meet the rigorous demands of temperature-controlled environments. The technology employed focuses on high performance, durability, and eco-friendliness. Here's an insight into the key technological features:

Insulation: PFI doors are constructed with advanced insulation materials, which provide superior thermal resistance and help maintain consistent temperatures. This minimizes energy loss, effectively reducing the environmental footprint and energy costs.

Seals and Gaskets: Airtight seals are crucial in preventing air infiltration. The doors are equipped with robust gaskets that seal gaps when closed, further enhancing temperature control and reducing energy consumption.

Door Materials: The doors are made with a variety of materials, including stainless steel and aluminum, chosen for their lightweight, corrosion resistance, and excellent thermal properties. Such materials ensure long-term reliability and performance in diverse settings.

Automation: Automatic sliding and roll-up designs are integrated with smart technology that allows for hands-free operation, reducing the chance of temperature fluctuations and increasing efficiency during operations.

Safety Features: Built with safety in mind, the doors include emergency release mechanisms, motion sensors, and alarms to prevent accidents and ensure safe operation for employees.

Sustainability: The technology behind these doors supports sustainability goals. By improving thermal efficiency and reducing energy consumption, PFI's doors contribute to the warehouse or facility's overall green initiatives.

To sum up, PFI's cold storage doors employ a synergy of advanced materials, smart design, and eco-friendly practices, ensuring that businesses can operate more efficiently while also contributing to a sustainable future.

Maximizing Shelf Life: The Importance of Consistent Temperatures

Ensuring the longevity and quality of perishable goods rests heavily on maintaining consistent temperatures within cold storage environments. Variations in temperature, even minor ones, can prompt the growth of bacteria or lead to the degradation of products. PFI cold storage doors play a pivotal role in this aspect by providing a seal that is not only reliable but also resilient against daily operational wear and tear.

One key factor in maximizing shelf life is preventing thermal leakage. PFI cold storage doors are engineered with advanced insulation materials and gaskets, forming an airtight barrier that reduces temperature fluctuations caused by external conditions. This uniform temperature maintains the integrity of perishables, consequently extending their shelf life.

- Energy Efficiency: Reduced energy expenditure is another significant result of consistent temperatures. As temperature-variance demands on refrigeration systems decrease, so does the energy required to maintain set levels, leading to cost savings.

- Product Quality: The uniformity of the internal climate ensures that the quality of products is preserved. Fluctuations can cause spoilage or freezer burn, affecting both taste and texture.

- Regulation Compliance: Regulatory bodies often set strict guidelines for temperature control in food storage. Adherence to these standards is critical for operations, and PFI cold storage doors aid in compliance, minimizing the risk of costly penalties.

- Reduced Operation Costs: An effective cold storage solution minimizes the frequency of door failures and associated maintenance or repair costs, contributing to increased operational efficiency.

In summary, the consistent temperatures provided by PFI cold storage doors are crucial for the maximization of shelf life. They offer an indispensable component in the chain of maintaining product freshness, safety, and ultimately, customer satisfaction.

Energy Efficiency: Reducing Operational Costs with PFI Doors

When managing a cold storage facility, the significance of energy efficiency transcends mere environmental stewardship; it directly influences the bottom line. PFI (Perimeter Frame Insulated) doors are at the forefront of reducing operational costs by addressing one of the largest energy leaks in such facilities – the doorways. Their design incorporates several features crucial for minimizing energy waste:

Insulation: PFI doors are furnished with high-grade insulation materials. These materials maintain the internal temperature, thereby decreasing the workload on refrigeration systems.

Sealing Technology: The doors are equipped with advanced sealing technology. Edges are snugly sealed to prevent the escape of cold air, which can lead to increased energy consumption due to temperature fluctuations.

High-speed Operation: The rapid open and close mechanism of PFI doors ensures minimal air exchange during entry and exit, curtailing the inflow of warm air and the outflow of cold air.

Durability: Constructed for endurance, PFI doors resist wear and tear from frequent use. This long-lasting quality reduces the need for replacements and maintenance-induced downtime, fostering continuous operations and energy savings.

Smart Controls: Integration with smart control systems allows for automated operation of PFI doors. This can include tailored opening sizes based on the type of traffic and closure timings to optimize energy usage.

By incorporating PFI doors, facilities can realize substantial energy savings. Operational costs are driven down not just through reduced energy bills but also by decreasing the strain on refrigeration systems, extending their lifecycle, and diminishing maintenance costs. This investment in energy-efficient entryways pays dividends, reinforcing the sustainability of cold storage operations while buttressing their financial viability.

Customization Options for PFI Cold Storage Doors

PFI cold storage doors offer an array of customization options designed to meet the unique needs of various industries and applications. Each feature is carefully crafted to enhance efficiency, offer superior insulation, and integrate seamlessly with existing systems.

Size Specifications: Whether you need a standard-sized door or a large, custom-built model, PFI can accommodate. They can manufacture doors in a wide range of dimensions to match the specific spatial requirements of your facility.

Temperature Control: PFI cold storage doors can be configured for different temperature zones, from chilled to deep-freeze, ensuring optimal performance and energy efficiency for a diverse array of controlled environments.

Door Material: Clients can select from several materials such as stainless steel, aluminum, or other alloys that are resistant to corrosion and suitable for harsh environments. This selection ensures durability and longevity in maintaining temperature integrity.

Insulation Type: High-quality insulation options are available, which can be tailored to meet the thermal resistance requirements of the client's operations, thus keeping energy consumption to a minimum.

Access Control: Integration of state-of-the-art access control systems including biometric scanners, card readers, or keypad entries can be added, allowing for enhanced security and controlled access to sensitive areas.

Door Operation: Choose between manual or automatic door operation systems. Automated doors with high-speed opening and closing mechanisms can improve traffic flow and reduce temperature fluctuations.

Color and Finish: The door's color and finish can be customized to fit the aesthetic of your facility or to comply with safety standards, including the use of protective coatings for added resilience against wear and tear.

Safety Features: Incorporate safety mechanisms such as emergency exit devices, visual and audible alarms, and anti-fog systems to ensure compliance with safety regulations and to protect personnel.

Sealing Solutions: Superior sealing solutions such as gaskets and air curtains can be included to minimize air infiltration, maintaining stable internal conditions and preventing condensation.

Energy-Saving Components: Options like double or triple pane windows, thermal breaks, and low-energy consumption motors contribute to an overall reduction in energy use, resonating with sustainability objectives.

Through these customization options, PFI cold storage doors are engineered to support diverse industry requirements, promoting efficiency, and sustainability within controlled environments.

The Impact of PFI's Door Durability on Perishable Goods Storage

When discussing the storage of perishable goods, the integrity of cold storage facilities is paramount. PFI's robust cold storage doors play a significant role in maintaining the ideal environment for such goods. Durable doors reduce the risk of temperature fluctuations, which can be detrimental to perishable items. Here's how the sturdiness of PFI doors impacts perishable goods storage:

Temperature Control: PFI doors are engineered to withstand frequent openings and closings while maintaining a consistent temperature inside the storage facility. This is crucial for perishable goods, which require strict temperature regulation to prevent spoilage.

Airtight Seal: The durability of PFI doors ensures an airtight seal, preventing warm air infiltration and humidity variations. This helps in keeping the internal atmosphere stable, which prolongs the shelf-life of perishable products.

Energy Efficiency: Strong, well-sealed doors minimize the loss of cooled air, thus reducing energy consumption. Energy-efficient doors are not only better for the environment but also cost-effective in the long run.

Reduced Maintenance and Repair Costs: The resilience of PFI doors means fewer repairs and replacements. This results in less disruption to the storage environment and ensures perishable goods are not exposed to unsuitable conditions during maintenance.

Enhanced Security: The robustness of the doors fortifies the facility against unauthorized access that can potentially introduce contaminants or temperature breaches, safeguarding the stored perishables.

In summary, the incorporation of durable PFI cold storage doors indirectly yet significantly influences the freshness, quality, and safety of perishable goods. Investing in such resilient infrastructure is a proactive step toward ensuring that perishable products are stored under optimal conditions, thus ultimately benefiting both the storage facility operators and the end consumers.

Safety Features of PFI Cold Storage Doors

Preservation of perishable goods is paramount in industries such as food, pharmaceuticals, and biotechnology. The cold storage doors by PFI (Panel Fab Inc.) not only aim to maintain optimal temperatures and energy efficiency but also give considerable emphasis to safety features. An understanding of these features is crucial for operators to ensure a secure work environment.

Integrated Alarms and Warning Systems: PFI doors come equipped with alarms that can alert personnel to open doors, temperature fluctuations, or system malfunctions. These alerts can be both audible and visual, ensuring that they cannot be easily missed even in a busy warehouse environment.

Emergency Release Mechanisms: In the event of an emergency or power failure, it's essential that staff can exit the cold storage area immediately. PFI cold storage doors include internal safety release mechanisms to prevent accidental entrapment and allow for quick evacuation.

Touchless Sensors: To maintain the highest hygiene standards and minimize the spread of contaminants, PFI doors can be fitted with motion sensors for touchless opening and closing. This feature not only enhances safety but also contributes to the operational efficiency and cleanliness of the storage environment.

Insulated Panels and Gaskets: The doors are constructed with high-quality insulated panels and gaskets to prevent frost buildup and ice formation, which could potentially lead to slip-and-fall accidents. This design feature helps maintain a clear and safe threshold while conserving energy.

Impact Resistance: In environments where heavy equipment and frequent traffic are the norms, PFI cold storage doors are designed to withstand impacts. Durable materials and construction prevent door damage that can lead to safety hazards or energy loss.

Thermal Breaks: To prevent cold transfer which can cause icy conditions on the floor outside of the cold room, PFI doors employ thermal breaks. By isolating the cold temperatures to the interior of the cold storage, this design minimizes the risk of slip hazards outside the door area.

PFI's attention to safety measures in cold storage doors showcases its commitment to creating products that not only meet the rigorous demands of temperature control but also prioritize the well-being of the individuals operating within these environments.

How PFI's Cold Storage Doors Comply with Industry Standards

PFI's cold storage doors are meticulously engineered to meet or exceed the rigorous demands of industry standards, ensuring optimal performance in maintaining cold chain integrity. Their compliance is rooted in several critical areas:

Energy Efficiency: PFI doors are designed with superior insulation materials and innovative sealing technologies that minimize energy leakage. This design characteristic aligns with the specifications of the International Energy Conservation Code (IECC) and the Energy Independence and Security Act (EISA) for energy efficiency in industrial equipment.

Safety Standards: Safety is paramount in cold storage applications. PFI doors adhere to Occupational Safety and Health Administration (OSHA) regulations by incorporating features such as emergency exit functionalities, anti-entrapment systems, and visibility aids to prevent accidents and ensure the safety of personnel.

Hygienic Design: The food industry has strict cleanliness and sanitation standards, notably those from the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA). PFI cold storage doors are constructed with materials that resist corrosion, impede bacterial growth, and are easy to clean, consequently supporting these standards.

Construction Quality: PFI cold storage doors conform to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) standards for the construction of insulated doors and panels. The use of quality materials and manufacturing practices ensures durability and longevity.

Environmental Compliance: PFI is committed to sustainability, producing doors that are compliant with directives such as the Leadership in Energy and Environmental Design (LEED) and the Restriction of Hazardous Substances Directive (RoHS). These certifications underscore PFI's dedication to producing doors that are as environmentally responsible as they are functional.

By meeting these industry standards, PFI's cold storage doors not only ensure regulatory compliance but also provide customers with confidence in their investment, knowing that they benefit from enhanced operational efficiency, safety, and sustainability.

The Environmental Benefits of Using PFI Cold Storage Solutions

In today's environmentally conscious world, the use of Premier Facility Installation (PFI) cold storage solutions stands out, not only for their operational efficiency but also for their significant environmental benefits. The incorporation of PFI technologies in cold storage doors directly contributes to several key areas of environmental sustainability.

Energy Efficiency: PFI cold storage solutions are designed to minimize energy consumption. These solutions typically include high-speed doors that open and close rapidly, reducing the amount of time the doors stay open and thereby limiting the escape of cold air. This design mitigates energy loss and reduces the workload on cooling systems, leading to lower electricity usage and decreased greenhouse gas emissions.

Advanced Insulation: PFI cold storage doors are equipped with superior insulation materials, often exceeding standard requirements. Enhanced insulation helps maintain consistent internal temperatures with less energy output. The result is a reduced carbon footprint, as the facility consumes less energy to keep products at the desired temperature.

Durability: The robust construction of PFI cold storage doors ensures a longer lifespan, meaning fewer resources are needed for repairs and replacements over time. This durability translates to less material waste and contributes to a more sustainable lifecycle for the cold storage facility.

Reduce Refrigerant Leakage: High-quality seals and fitments in PFI solutions significantly lower the risk of refrigerant leaks. Refrigerants can be potent greenhouse gases, and minimizing leakage plays a critical role in protecting the environment.

By focusing on energy conservation, robustness, and the prevention of refrigerant leaks, PFI cold storage solutions provide a more sustainable option for businesses aiming to reduce their ecological impact. These solutions ultimately help to create a more sustainable cold chain, thus supporting global environmental goals.

A Case Study: Real-world Application of PFI's Cold Storage Doors

In the competitive landscape of temperature-sensitive storage and distribution, a leading food processing company sought to improve its operational efficiency and reduce energy costs. The company, with multiple distribution centers, faced challenges with maintaining consistent temperatures and preventing energy loss due to frequently accessed storage areas. The solution presented itself in the form of PFI's advanced cold storage doors.

The food processing company implemented PFI's state-of-the-art insulated sliding doors across their main distribution center. This upgrade was part of a larger initiative to enhance sustainability and operational performance. The features which made PFI's doors an optimal solution include:

- High-speed opening and closing mechanisms that minimize the time the door remains open, thus reducing cold air escape.

- Superior seal integrity that prevents temperature fluctuations and maintains consistent storage conditions, crucial for food preservation.

- Durable construction engineered to withstand heavy usage while requiring minimal maintenance, promoting longevity and reliability.

- Energy-efficient design that results in substantial savings on power bills while contributing to the company's green initiatives.

Post-installation, the company experienced a marked improvement in its operational metrics. Energy consumption reduced by a notable margin, directly impacting the bottom line with cost savings. Moreover, the temperature within the storage facilities stabilized, ensuring compliance with food safety standards and enhancing product quality.

This case study exemplifies the tangible benefits of integrating PFI's cold storage doors into a facility that demands high efficiency and sustainability. The doors not only met the company’s immediate needs but also positioned them favorably for future growth and industry compliance.

How to Choose the Right PFI Cold Storage Door for Your Business

Selecting the appropriate cold storage door manufactured by Panel-Fab, Inc. (PFI) is crucial for ensuring operational efficiency and sustainability. Businesses must consider several key factors before making a decision:

Environmental Conditions

- Temperature Requirements: Assess the minimum and maximum temperature ranges needed for your stored products.

- Humidity Control: Consider the level of humidity control necessary to preserve product integrity.

Traffic Frequency

- Door Opening Cycles: Evaluate the number of times doors will be opened and closed daily. High traffic areas require more durable doors with faster opening and closing speeds.

Size and Space Constraints

- Door Dimensions: Measure the size of the openings. Larger doors may require additional safety features.

- Space Limitations: Ensure there is enough surrounding space for the door to operate without obstruction.

Energy Efficiency

- Insulation Properties: Look for doors with high R-values for better insulation to maintain internal temperatures and reduce energy consumption.

- Seal Quality: Ensure the doors have proper sealing to prevent air infiltration.

Safety and Compliance

- Safety Features: Choose doors with built-in safety mechanisms to protect workers and products.

- Regulatory Compliance: Ensure the doors meet industry standards and local building codes.

Maintenance and Durability

- Maintenance Requirements: Ensure doors have easily replaceable components and require minimal maintenance.

- Material Durability: Look for doors constructed from materials that can withstand the wear and tear of your operational environment.

Additional Features

- Automation: Consider if automated doors would improve operational efficiency.

- Visibility: Decide if doors need windows for visibility and safety.

Through careful consideration of these factors, businesses can identify the PFI cold storage door that best meets their specific needs, optimizing both efficiency and environmental sustainability.

Installation and Maintenance of PFI Cold Storage Doors

Installing PFI (Perishable Freight Inc.) cold storage doors is a critical step in ensuring an efficient and sustainable operation. These doors are designed to maintain optimal temperatures within a cold storage facility while minimizing energy consumption. Proper installation and maintenance are essential for their performance and longevity.

Installation

Professional Installation: PFI cold storage doors should be installed by qualified professionals to ensure they function correctly. These technicians are trained to handle the specific demands of cold storage installations.

Sealing and Insulation: Perfect sealing is critical to prevent air leakage. Technicians will ensure the door frame is level, and the door properly aligns with it. Quality insulation around the door perimeter is essential to maintain temperature control.

Testing: After installation, doors should be tested for proper sealant and balance. Doors must open and close with ease and provide a proper seal when closed.

Maintenance

Regular Inspections: Perform routine inspections for wear and tear, particularly in the sealing gaskets and the mechanical parts that experience frequent movement.

Cleaning: Regular cleaning is vital to maintain the effectiveness of the doors. Residues from daily operations can build up on the surfaces, affecting the door seals.

Lubrication: To ensure smooth operation, moving parts require periodic lubrication. This prevents stiffness and wear of the components.

Prompt Repairs: Address any issues immediately. Delays can lead to increased energy costs and potential temperature regulation problems.

Maintaining PFI cold storage doors is not only about preserving the product's quality but also about supporting energy efficiency and sustainability goals. Adhering to a routine maintenance schedule guarantees the integrity of the cold storage environment and prolongs the life of the doors.

Return on Investment: Analyzing the Cost-Benefits of PFI's Cold Storage Doors

When evaluating the cost-benefits of PFI's cold storage doors, one must consider both the initial expenditure and the long-term savings. These doors are engineered to provide superior insulation, leading to reduced energy consumption. In cold storage facilities, where temperature control is crucial, this translates to significant cost savings over time.

Energy Efficiency: PFI's doors are designed to minimize air leakage, maintaining consistent temperatures and reducing the workload on cooling systems. This efficiency can substantially lower energy bills, a primary operating cost for cold storage facilities.

Durability and Maintenance: Constructed with high-quality materials, these doors are built to withstand the rigorous conditions of a cold storage environment, resulting in fewer repairs and replacements. The longevity of PFI's doors ensures a lower total cost of ownership.

Operational Speed: With rapid opening and closing mechanisms, PFI's doors help maintain the cold chain by limiting the amount of warm air that can enter during operation. This feature not only contributes to energy savings but also enhances overall operational efficiency by minimizing the time needed for goods to move in and out.

Regulatory Compliance: By maintaining precise temperature control, PFI's doors aid facilities in meeting strict industry regulations. This compliance can prevent costly fines and help protect against product loss or contamination.

Environmental Impact: As companies increasingly aim to meet sustainability goals, PFI's cold storage doors contribute to these initiatives by reducing the carbon footprint of facility operations.

Investing in PFI's cold storage doors is not merely a purchase but a strategic decision that yields dividends in the form of energy savings, sustainability, and compliance benefits. The doors act as a gateway to not only preserving goods but also safeguarding the financial health of the storage facility.

Cold Room Doors and Modular Cold Rooms

PFI offers suitable solutions for your needs with insulated and semi-insulated cold room door models & modular cold rooms.

What is cold room door?

Cold room doors are divided into two as insulated and semi-insulated doors. Insulated cold room doors consist of horizontal sliding, vertical sliding and hinged doors. They have different blade alternatives according to the temperature to be protected.

PFI sliding doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Lateral sliding doors work with the principle of sliding to the right or left. Single or double blade options are available. Vertical sliding doors work with the principle of sliding to up and down. All PFI lateral sliding doors can be equipped with an automation system, a lock, a viewing window, a kick plate, etc.

PFI hinged doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Single or double blade options are available. All PFI hinged doors can be equipped with an automatic door closer, a viewing window, a kick plate, etc.

Semi-insulated doors are divided into two as service and taf/swing doors. Semi-insulated doors are produced from 40mm blade. They are mostly preferred as transition doors of rooms that do not have temperature differences.

CONTACT US

Where Are Modular Rooms Used?

PFI modular rooms are produced from 80mm and 100mm panels. Rooms consisting of 80mm panels are generally used at (+) positive degrees, rooms consisting of 100mm panels are generally used at (-) negative degrees.

- Thanks to PFI cold and freezer room doors, you can keep your products at suitable temperatures. PFI cold room doors, which can be produced in different thicknesses, can offer a suitable solution for all your needs. Our scope of product range has suitable alternatives that can work between +80 degrees and -80 degrees.

- Our cold and freezer room door models also offer different frame alternatives. We have 2 main options for frame, Aluminum or PVC frame. Our cold room door frames can be adapted to any wall or panel.

- PFI cold storage room doors also adapt to the color designs of your facilities with its different color alternatives. We can offer various color alternatives, our PFI cold room doors will meet your aesthetic expectations as well as their durability.

- Our cold room doors can be equipped with many features if desired. The most frequently used accessories in the cold room door; motor, locks, pedestrian doors, viewing or openable windows.

- Apart from the cold storage doors, PFI produces hygienic and non-heat-permeable PVC profiles which are used in modular cold rooms. These PVC profiles offer a much faster and stylish solution when it is compared with traditional system (long assembly time, visual problems, etc.).

Our company, which is the leader to produce cold storage, will provide you with the highest quality products and technical support. You can contact with our sales representatives for detailed information about PFI cold door rooms and special pricing for your specific projects.

FAQ

- Are the products manufactured in Italy? PFI carries out its production in its facilities in Adana Organized Industrial Zone.

- Does PFI only manufacture cold storage doors? In addition to cold storage doors, PFI also manufactures industrial doors and loading bay systems solutions.

- Are the products of Italian origin? Our products are produced with Italian technology and are 100% Turkish origin.

- Does PFI produce in standard sizes? PFI can manufacture in desired dimensions according to your project.

- Are cold room doors produced for negative degrees only? Cold room doors are used in both + positive and - negative degrees.

Cold Room Door Prices

You can reach detailed information about our cold room door prices by contacting our customer representatives.