Hydraulic Dock Levelers

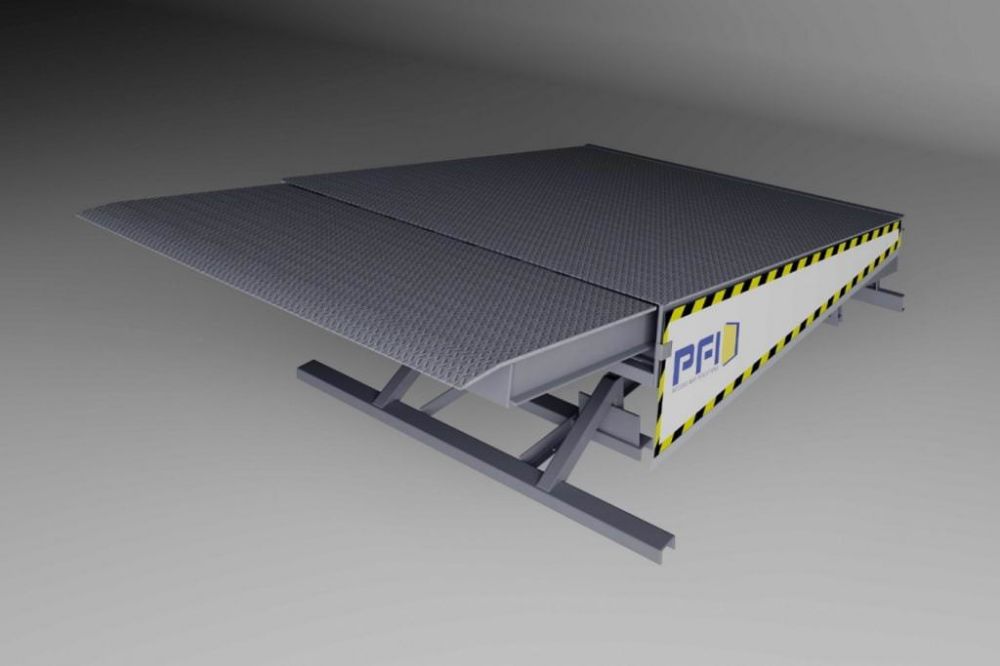

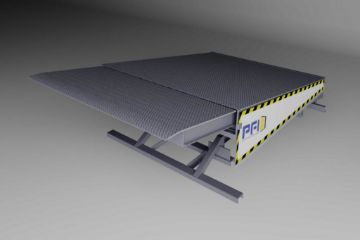

Swinging lip hydraulic dock levelers are the most commonly used type in loading and unloading operations. The structure of swinging lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the swinging lip dock leveler are made of 6-8 mm thickness of drop pattern SD37 quality galvanized steel sheet. C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

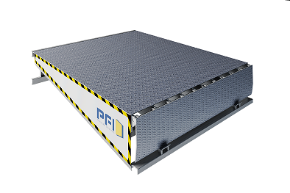

Telescopic lip hydraulic dock levelers are the most suitable solutions for places where high thermal insulation is required. The structure of telescopic lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the telescopic lip dock leveler are made of 8-10 mm thickness of drop pattern SD37 quality galvanized steel sheet. C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It has a beveled edge and is angled to better adhere to the truck bed. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

PFI manufactures aluminum hydraulic dock levelers. The advantages of using aluminum compared to galvanized steel are: prevention of rust formation and ease of shipping. It is the most ideal solution for corrosion resistance and for the storage of cooled foods.The structure of our swinging lip aluminum dock levelers is designed to be used in forklift eyes. In this way, our dock levelers can be easily installed to the pit by a forklift. The use of aluminum guarantees greater durability over time compared to standard loading dock levelers, as it does not require surface retouching (paint galvanizing) and does not rust. For these reasons, it is an excellent choice for the cold logistics industry. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

Dock houses are economical insulation solutions that contribute to energy savings and improve the working environment. These solutions combine all the components required for the loading unit: dock levelers, dock shelters and sectional doors. A dock house is created by covering insulated panels of 40mm thickness on a galvanized steel frame. The ceiling structure is designed with a slight inclination for rainwater and snow that may accumulate on it. The dock house creates a ready-to-use space inside the building by allowing the loading and unloading area to be moved outside the building. It does not require major building renovation. It is the system used to prevent heat loss during loading in insulated loading areas.

Hydraulic Dock Levelers Production

Hydraulic dock levelers increase safety, save time and regulate efficiency where heavy traffic and product transportation proceeds.

PFI dock levelers are divided into three as swinging lip hydraulic dock levelers, telescopic lip hydraulic dock levelers, swinging lip aluminum dock levelers.

Swinging lip hydraulic dock levelers are the most used dock leveler type in loading and unloading operations. The structure of swinging lip hydraulic dock levelers , consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the hinge lip hydraulic dock levelers are made of 6-8 mm thickness of drop patterned SD37 quality galvanized steel sheet.

Telescopic lip hydraulic dock levelers are the most suitable solutions for places where high thermal insulation is required. The structure of telescopic lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the telescopic lip dock leveler are made of 8-10 mm thickness of drop pattern SD37 quality galvanized steel sheet.

C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

PFI also manufactures aluminum hydraulic dock levelers.

What are the main features of swinging lip hydraulic dock levelers ?

Swinging lip hydraulic dock levelers are the most used dock leveler type in loading and unloading operations. The structure of swinging lip hydraulic dock levelers , consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the hinge lip hydraulic dock levelers are made of 6-8 mm thickness of drop patterned SD37 quality galvanized steel sheet. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It has a beveled edge and is angled to better adhere to the truck bed. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

What are the main features of telescopic lip hydraulic dock levelers ?

Telescopic lip hydraulic dock levelers are the most suitable solutions for places where high thermal insulation is required. The structure of telescopic lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the telescopic lip dock leveler are made of 8-10 mm thickness of drop pattern SD37 quality galvanized steel sheet. C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It has a beveled edge and is angled to better adhere to the truck bed. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

What are the main features of swinging lip aluminum dock levelers ?

PFI manufactures aluminum hydraulic dock levelers. The advantages of using aluminum compared to galvanized steel are: prevention of rust formation and ease of shipping. It is the most ideal solution for corrosion resistance and for the storage of cooled foods.The structure of our swinging lip aluminum dock levelers is designed to be used in forklift eyes. In this way, our dock levelers can be easily installed to the pit by a forklift. The use of aluminum guarantees greater durability over time compared to standard loading dock levelers, as it does not require surface retouching (paint galvanizing) and does not rust. For these reasons, it is an excellent choice for the cold logistics industry. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

You can contact our experienced sales representatives for detailed information about PFI dock levelers and special pricing upon your projects.

FAQ

- Are hydraulic dock levelers manufactured in Italy? PFI carries out all its production in its facilities in Adana Organized Industrial Zone.

- Does PFI manufacture other products besides hydraulic dock levelers? Besides hydraulic dock levelers, PFI also manufactures industrial doors, loading systems and cold room door solutions (cold room doors / sectional doors / dock levelers / dock shelters etc.).

- Are the products of Italian origin? Our products are produced with Italian technology and are 100% Turkish origin.

- Does PFI produce in standard sizes? PFI can manufacture in desired dimensions according to your project.

- How many types of dock levelers does PFI manufacture? PFI dock levelers are divided into three as hinge lip hydraulic, telescopic lip hydraulic, swinging lip aluminum.

Advantages of Dock Levelers

Hydraulic dock levelers offer several advantages for facilities that require efficient and safe loading and unloading of goods. Some of the key benefits include:

Easy operation: Hydraulic dock levelers are simple to operate, usually with a push of a button, which reduces the time and effort needed to position the leveler.

Increased safety: These levelers provide a smooth transition between the dock and the truck, minimizing the risk of accidents or injuries to workers and potential damage to equipment.

Durability: Hydraulic systems are built to withstand heavy loads and frequent use, making them a reliable choice for high-traffic facilities.

Low maintenance: Hydraulic dock levelers generally require less maintenance than their mechanical counterparts, as they have fewer moving parts that can wear out or break down.

Automatic height adjustment: These levelers can automatically adjust to varying heights of truck beds, making them versatile for handling different types and sizes of trucks.

Enhanced energy efficiency: Hydraulic dock levelers help maintain a better seal between the truck and the dock, reducing energy loss and improving temperature control within the facility.

Weather resistance: Hydraulic levelers can better withstand harsh weather conditions, such as extreme temperatures, rain, or snow, without compromising their performance.

Customization: Hydraulic dock levelers can be tailored to meet the specific needs of a facility, such as load capacity, size, and other features.

Reduced downtime: In the event of a power failure or malfunction, hydraulic levelers can be operated manually, ensuring minimal disruption to operations.

Improved productivity: The ease of use, reliability, and safety features of hydraulic dock levelers contribute to a more efficient loading and unloading process, ultimately boosting overall productivity.

Hydraulic Dock Leveler Prices

The price of a hydraulic dock leveler can vary widely depending on several factors such as size, load capacity, materials, features, and brand. While I cannot provide specific prices, I can give you a general idea of the price range to expect.

For a standard hydraulic dock leveler, prices typically start around $4,000. However, it's important to note that these prices can change over time due to market conditions, and additional costs for installation, customization, and accessories should also be considered.

When comparing prices, make sure to consider factors such as the leveler's weight capacity, size, safety features, warranty, and overall quality. It's also a good idea to request quotes from multiple suppliers to get a better understanding of the market and find the best deal for your specific needs.

Remember that while price is an important consideration, it shouldn't be the only factor when choosing a hydraulic dock leveler. Consider the long-term benefits of investing in a quality product that meets your facility's requirements and provides a safe and efficient work environment.

You can reach detailed information about our hydraulic dock leveler prices by contacting our customer representatives.

You may be interested : What is dock leveler?