Loading Bays Solutions

Sectional Doors are formed as horizontal panels that are joined on top of each other and are are opened and closed by moving upwards within vertical rails. These insulated, silent and long-lasting doors c/w motorized or manual alternatives; they are widely preferred in industrial facilities with their aesthetic, economic and functional advantages. They offer alternative application options with minimum space for your current need. All PFI sectional doors are manufactured in accordance with international quality standards. (EN13241:2003+A2:2016)

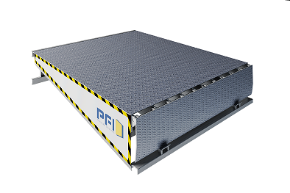

Swinging lip hydraulic dock levelers are the most commonly used type in loading and unloading operations. The structure of swinging lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the swinging lip dock leveler are made of 6-8 mm thickness of drop pattern SD37 quality galvanized steel sheet. C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

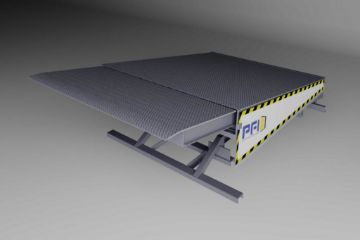

Telescopic lip hydraulic dock levelers are the most suitable solutions for places where high thermal insulation is required. The structure of telescopic lip hydraulic dock levelers, consisting of lip, platform and frame, is made of RAL7016 painted galvanized steel sheet. The main platforms of the telescopic lip dock leveler are made of 8-10 mm thickness of drop pattern SD37 quality galvanized steel sheet. C and L shaped profiles are strengthened by welding to the main platform. The lips of dock levelers are made of 12-13mm thickness of SD37 quality galvanized steel sheet with drop pattern. It has a beveled edge and is angled to better adhere to the truck bed. It is produced in accordance with EN 1398 norms. It can reach up to 640 mm above the loading area and up to 300 mm below the loading area.

Standard dock shelters are the most common model of dock shelters. They are used where high thermal insulation is not required. It consists of an aluminum profile attached to the outer wall of the loading compartment, a PVC sheet surrounding the profile, and black PVC coated sheets at the front to stick to the truck.

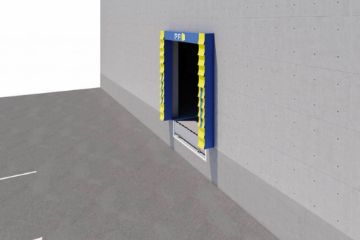

Inflatable dock shelters are generally used in areas where thermal insulation is highly required. It is the one of the most critical part of cold chain logistic operations. Inflatable dock shelters inflates the top and side cushions, by a fan, until they stick to the walls of the vehicle. This system is definitely the most practical and convenient solution because it automatically adapts to any isothermal vehicles size.

Dock shelters with cushions are used to minimize air permeability when approaching the loading areas of small vehicles other than trucks. The dimensions of these dock shelters are determined according to the size of the sectional doors used in the loading area. The clear passage dimensions of the sectional doors and the interior dimensions of the dock shelters will be the same. Although the standard cushion widths are 300mm, pad widths can be increased upon request.

Loading Systems

Loading and unloading systems mostly serve for logistics industry. Thanks to its mobility, it increases the speed and safety of the loading operation and prevents loss of time.

PFI loading and unloading systems; It consists of sectional doors, high speed PVC roll-up doors, hydraulic dock levelers and dock shelters. Loading systems create a bridge between industrial facilities and vehicles approaching the building.

Loading systems products are as follows.

- Sectional doors consist of a combination of PU (polyurethane) injected panels which are extremely resistant to outdoor conditions. Generally, they are used for loading and unloading area doors where the thermal insulation of the facility is a priority. Thanks to their high insulation feature, we can preserve your facility from outdoor conditions. Sectional doors are the most preferred doors in industrial doors field.

- PFI hydraulic dock levelers perform fully automatic loading and unloading functions at the highest safety level. Hydraulic dock levelers, which can be produced in desired color and different properties, provide functionality and convenience in loading and unloading operations. The bending-resistant steel platform structure smooths the side slope of the vehicle even in uneven load distribution. We have swinging lip, telescopic lip and aluminum hydraulic dock leveler alternatives which can be used according to your facility needs.

- Dock shelters are used for preventing materials and facility from outside weather conditions during loading and unloading process. These systems, with different colors and features, provide functionality and convenience in your loading and unloading processes. We have 3 different alternatives as standard, inflatable and pillow versions.

- High speed PVC roll-up doors produced by PFI are fast, durable, energy-saving and designed for all kinds of industrial use. It is used to separate the sections of the facilities. By the design of curtain of the door, high speed doors can act fast and provides effective protection against heat, dust and moisture. PFI high speed PVC roll-up doors help you to achieve the goals of your operation. It saves energy, reduces total operating costs, restructures traffic flow and improves logistics. Our high speed doors are produced in accordance to all international standards and maintenance-free.

You can contact our sales representatives for detailed information about PFI loading and unloading systems and special pricing for your specific projects.