Cold Chain Solutions

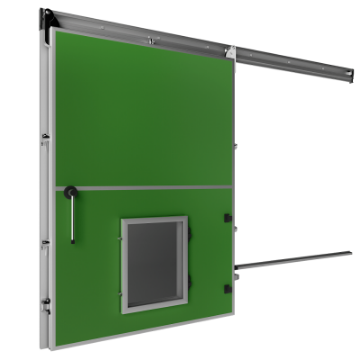

PFI vertical sliding doors are basically divided into two type. The doors of the rooms to be kept at 0⁰ and above temperatures are called the cold room door, and the doors of the rooms to be kept below 0⁰ temperatures are called the freezer room door. Vertical sliding doors work with the principle of sliding to up and down. All PFI vertical sliding doors can be equipped with an automation system, a lock, a viewing window, a kick plate, etc. Moreover it is provided with a “parachute break” safety device against steel cable break system or malfunction.

The STN 9 and STN 12 sliding doors can be equipped in order to be used for controlled atmosphere applications. The special closed cells air foam gaskets, together with the exclusive stainless steel eccentric clenching system, guarantee a perfect gas tightness, and a thermal seal too. These doors are provided with a glazed inspection hatch, that can even be supplied to be fixed directly on the cold room wall.

PFI manufactures sliding doors provided with meat rail slide-way (SPG) in two versions. The first one is called “swan neck” due to the cantilever stainless steel structure that keeps the slide way passage free. The second one is called “interrupted rail” and presents the sliding door track positioning just below the slide way passage. Therefore the sliding track presents an interruption to allow the meat rail to pass through.

PFI monorail hinged doors (CPG) are specially produced according to the monorail dimensions. By using a special hygienic brush and panels of the same color as the door installed inside the frame, we are minimizing air passage. They are manufactured as single or double blade. All PFI hinged doors can be equipped with an automatic door closer, a viewing window, a kick plate, etc.

PFI TAF doors are used as passage doors between production, processing, and corridors where thermal insulation doesn't exist. TAF doors are produced as single or double blade alternatives. These doors blades are equipped with a viewing window and can be fixed at 90 degrees. They belong to semi-insulated door class which have a 40 mm thickness of monolithic blade insulated with high density PU foam injection. PFI TAF doors are used to allow people or wheelbarrows to move quickly and easily to processing rooms in industrial kitchens, food, medicine and industrial facilities. These doors open 90 degrees in both direction. Plexiglass windows are used as standard on all door blades to avoid any accident.

Thanks to their durability and washable surfaces, PFI service doors are suitable for production offices, processing rooms, locker rooms and ablution areas in the food and pharmaceutical industry. These doors can be produced as single or double blades. They belong to semi-insulated door class which have 40 mm thickness of monolithic blade insulated with high density PU foam injection. PFI service doors are equipped with hinges made of composite material, cylinder lock of European origin and plastic ergonomic handles.

When considered necessary, using PVC curtains together with cold storage, frozen storage and shock room doors minimizes heat losses when doors are opened and increases economic productivity through energy saving. Furthermore, it prevents gas, dust and other particles getting into the room and provides hygiene. Easy to install and adaptable to negative temperatures, PVC curtains can be obtained in required sizes or like 50m rollers.